Don’t Get Spooked By Rubber Assembly! Treat Yourself to P-80® Lubricants!

Comments Off on Don’t Get Spooked By Rubber Assembly! Treat Yourself to P-80® Lubricants!Rubber assembly can be scary! So many parts…all different shapes and sizes. Trying to insert them into proper position without twisting or tearing can be quite a challenge. Don’t be tricked, treat yourself to P-80® Temporary Rubber Assembly Lubricants and slide parts easily into place.

Rubber is naturally slip-resistant making it difficult to install, remove or manipulate. It’s not unusual for rubber parts to slip during assembly and not go exactly where they’re intended: an O-ring may get twisted, a heater hose may not be fully inserted, a gap can appear in a waterproof seam. Successful assembly can be tricky. Improper assembly can lead to a multitude of problems including destroyed parts, warranty claims, recalls and worker fatigue or injury.

Help prevent problems such as ill-fitting, misaligned or damaged parts, rolling O-rings, uneven cuts or worker injury by relying on temporary rubber lubricants for assembly.

What Are P-80 Temporary Assembly Lubricants?

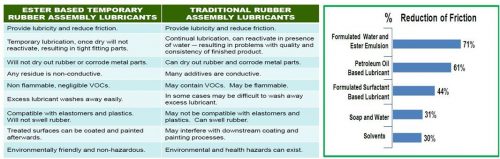

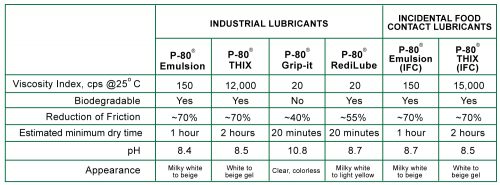

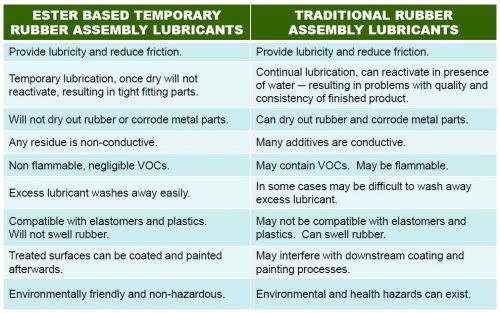

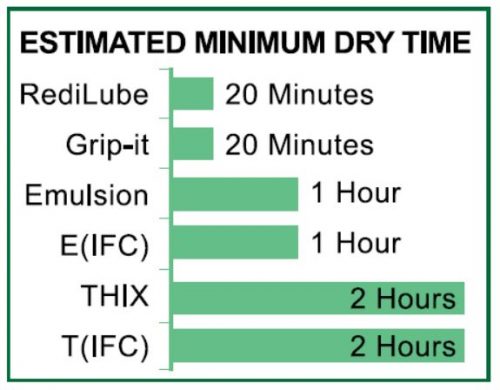

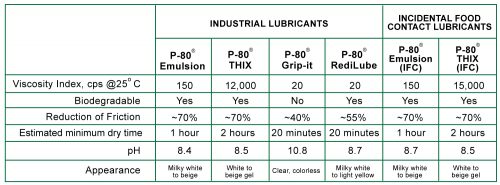

P-80 lubricants provide temporary lubrication. Once they dry, the lubrication ceases and will not reactivate, even when wet. P-80 lubricants are environmentally friendly, non-hazardous, and non-flammable, making them safe for workers and most plastics, rubbers, and metals. Most P-80 products are biodegradable.

Why Use Temporary Assembly Lubricants?

Reduce Installation Force:

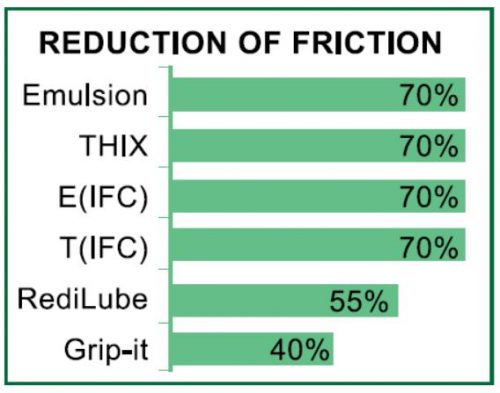

A thin film of lubricant applied to a part fills in any gaps, holes, or spaces between two surfaces, allowing them to slide across each other. By reducing the tension between the two surfaces, rubber parts can slide into place easily.

Achieve Closer Fits:

The force needed to install parts when a lubricant is used is greatly reduced, so engineers can design tighter fitting parts. Since the lubrication is only temporary, once dry, the parts stay in place.

Improve Product Performance:

Improper part alignment can lead to part failure and safety issues. Using lubricants is one way to ensure that mated parts are properly installed and will work as anticipated.

Increase Production Rates:

Paring the optimal lubricant with the right application technique speeds up production. An increase in lubricity, even by small amounts, is greatly appreciated by line operators required to maintain strict cycle times.

Help to Avoid Worker Injuries:

Assembly lubricants ease the installation process of many parts. Workers can more easily push parts into place, reducing the amount of musculoskeletal, slippage, and repetitive stress related injuries that can be caused by using too much force to insert a rubber part.

Treat yourself to P-80 Temporary Lubricants to remove the tricks from rubber assembly!

Want to try P-80 lubricants for your challenging rubber assembly applications? Request a free sample today!

Common O-ring installation problems include tearing, twisting, turning, pinching and overstretching. Incorrectly installed O-rings may cause leaks which can damage parts and equipment. O-rings that are properly installed can prevent leaks and increase part life.

Common O-ring installation problems include tearing, twisting, turning, pinching and overstretching. Incorrectly installed O-rings may cause leaks which can damage parts and equipment. O-rings that are properly installed can prevent leaks and increase part life.