Do You Need P-80® Temporary Rubber Assembly Lubricants?

Tweet

Print

Print

Have You Ever Struggled With Rubber Assembly?

How many times have you pushed a rubber hose onto a fitting only to find it wouldn’t slide into place because the fit was just too tight? Or, how about all of those seals and O-rings that twisted or tore because it took so much force to seat them? Remember the frustration you felt after pushing a grommet into place and then watching it pop right back out?

If so, you’ve probably experienced for yourself the excessive force needed to properly install hoses, seals, gaskets, O-rings and many other rubber parts. These tasks can be very frustrating and can often require considerable physical effort and time.

Rubber materials are inherently difficult to install, remove, or otherwise manipulate – even when wet. The slip-resistant nature of rubber creates a challenge during the assembly and repair of rubber parts. Since these parts play such an integral role in product function and design, it’s important to assemble them properly to avoid future problems with product performance.

Do Any Of These Assembly Problems Sound Familiar?

- Rolling O-rings

- Uneven cuts

- Misaligned parts

- Damaged parts

- Injured workers (sore muscles, slippage, repetitive stress injury)

If so, P-80® Temporary Rubber Assembly Lubricants may be the answer. When applied to rubber parts, P-80 lubricants reduce friction during assembly to make installation easier. Once dry the slipping action goes away and parts stay in place.

What Are The Advantages Of P-80 Temporary Assembly Lubricants?

Reduce Installation Force:

A thin film of lubricant applied to a part fills in any gaps, holes, or spaces between two separate surfaces, allowing them to slide across each other. By reducing the tension between the two surfaces, rubber parts can slide into place easily.

Achieve Closer Fits:

The force needed to install parts when a lubricant is used is greatly reduced, so engineers can design lower tolerance parts. Since the lubrication is only temporary, once dry, the parts stay in place resulting in a tight fit.

Improve Product Performance:

Improper part alignment can lead to part failure and safety issues. Using lubricants is one way to ensure that mated parts are properly installed and will work as anticipated.

Increase Production Rates:

Pairing the optimal lubricant with the right application technique speeds up production. An increase in lubricity, even by small amounts, is greatly appreciated by line operators required to maintain strict cycle times.

Help to Avoid Worker Injuries:

Assembly lubricants ease the installation process of many parts. Workers can more easily push parts into place, reducing the amount of musculoskeletal, slippage, and repetitive stress related injuries that can be caused by using too much force to insert a rubber part.

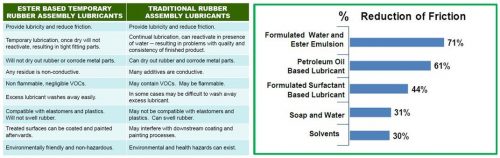

How Does P-80 Compare To Other Lubricants?

P-80 lubricants are temporary assembly lubricants, once dry the lubrication ceases and will not reactivate, even when wet. Additionally, P-80 lubricants are environmentally friendly, non-hazardous, and non-flammable, making them safe for workers and most plastics, rubbers, and metals. In fact, most P-80 products are biodegradable.

Which P-80 Lubricant Do I Need?

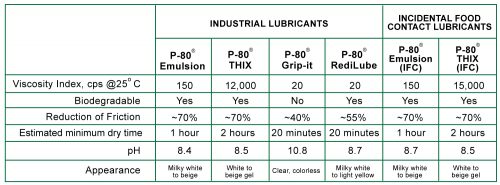

Since each assembly application is unique, IPC has developed different P-80 formulas so workers can choose the product that will work best for their particular application. P-80 is available in four ready-to-use industrial formulas, as well as two special formulas that are registered with the NSF as H1 lubricants approved for incidental food contact applications.

Many jobs can benefit from the reduced friction and increased safety provided by P-80 Temporary Rubber Assembly Lubricants. Use P-80 the next time you’re having trouble replacing pump seals, installing bushings, assembling O-rings, or pushing hoses onto fittings and you’ll discover for yourself how much easier assembly can be.

Any time you encounter rubber parts…P-80 can help!

Want to try P-80 lubricants for your challenging rubber assembly applications? Request a free sample today!

Tweet

Print

Print