Zymit® Pro Enzyme Cleaner

Enzyme cleaners are specialized products that help accelerate the process of breaking down organic waste and soils. In addition to helping eliminate stains, they can also fight the pungent odors that accompany many types of decomposing matter. Keep reading to broaden your understanding of how these cleaners work, when enzyme cleaners are particularly useful, and… Continue Reading Zymit® Pro Enzyme Cleaner

Choosing the Right Automotive Assembly Lubricant

Hoses, seals, O-rings, belts, pads, bushings, and grommets – what do they all have in common? These parts are all made of rubber and are found within your car. Automobile assemblies are complex and contain many moving parts. The average light vehicle in the US and Canada contains about 206 pounds of rubber, accounting for… Continue Reading Choosing the Right Automotive Assembly Lubricant

Helping You Choose the Right Solution for Medical Device Cleaning and Medical Instrument Cleaning

Whether your medical device is disposable, implantable, or reusable, it must be cleaned before use. Cleaning medical equipment is a crucial step in a successful disinfecting procedure. IPC offers a full line of precision cleaners, each with unique characteristics, that can provide you with the required level of cleanliness prior to disinfecting. IPC’s cleaners offer… Continue Reading Helping You Choose the Right Solution for Medical Device Cleaning and Medical Instrument Cleaning

Why Food Manufacturers Trust IPC’s Cleaners

Disinfectants and other sanitizing agents cannot adequately sanitize a surface with leftover food residue on it. These contaminants can harbor harmful germs and bacteria. Cleaning removes traces of dirt, debris, and dust and primes surfaces and equipment for disinfection. Simply put, cleaning is just as important as disinfecting, and that’s why selecting an appropriate cleaner… Continue Reading Why Food Manufacturers Trust IPC’s Cleaners

Micro Green Clean: A Greener Cleaner Choice

Micro Green Clean: A Greener Cleaner Choice Conventional non-green consumer and commercial cleaning products are potentially hazardous, carrying the risks of long-term illness due to over-exposure, asthma, chemical burns, irritation, or accidental ingestion by a person or pet. As the demand for effective cleaning products grows, manufacturers seek to develop effective formulations that contain more… Continue Reading Micro Green Clean: A Greener Cleaner Choice

IPC is DuBois – European Market

New year, more solutions! DuBois Chemicals acquired International Products Corporation (IPC) in July 2021. DuBois’ European operations in the Netherlands began managing the supply of IPC products and services for Europe in February 2022. IPC’s line of specialty chemical products, including cleaners and assembly lubricants, allows DuBois to expand their chemistry and process knowledge capabilities… Continue Reading IPC is DuBois – European Market

Gas & Diesel ASTM

P-80® Lubricants possess the unique property of being temporary rubber assembly lubricants. After assembly, the water dries, and the part is left securely in place. Due to the lubricating oils in our lubricants, a tiny amount of residue may remain on the parts. Sometimes, the question of how these residues may impact automotive fuels is… Continue Reading Gas & Diesel ASTM

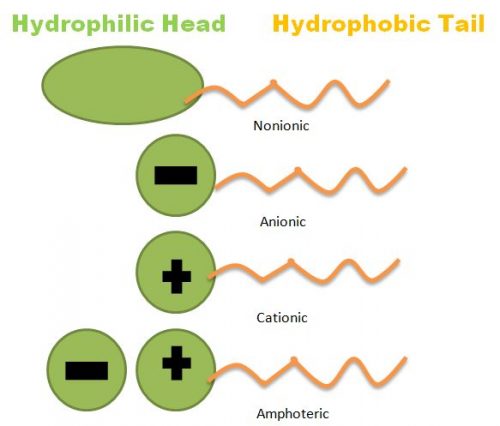

An Easy Guide to Understanding How Surfactants Work

What is a Surfactant? Surfactants are a primary component of cleaning detergents. The word surfactant means surface active agent. As the name implies, surfactants stir up activity on the surface you are cleaning to help trap dirt and remove it from the surface. Surfactants have a hydrophobic (water-hating) tail and a hydrophilic (water-loving) head. The… Continue Reading An Easy Guide to Understanding How Surfactants Work

P-80 for Bushing Pressing

Bushing pressing is a tough job. It takes a lot of force to get the insert seated correctly. In addition, the lubricant cannot be so strong that it slips back out. Our P-80®line of water-based temporary rubber assembly lubricants makes bushing pressing easy. Our P-80 lubricants are available in six unique water-based formulas that provide… Continue Reading P-80 for Bushing Pressing

Need to Validate Your Cleaning Procedures? We Can Help!

If you work in a regulated industry, you already know, there’s more than one way to validate a cleaning process. But which one is best for your process? The Bulk Pharmaceutical Chemicals and the Biotechnology Inspection Guide has established the expectation that cleaning procedures be validated—meaning that scientific data must show that the systems work… Continue Reading Need to Validate Your Cleaning Procedures? We Can Help!