How To Assemble Hoses And Seals With P-80® Temporary Rubber Lubricants

Tweet

Print

Print

Cars, trucks, buses, locomotives, motorcycles, boats, airplanes, refrigerators, dishwashers, washers and dryers, pumps, construction equipment, conveyor belts, cable assemblies, and machines…What do all of these familiar items have in common?

All of them are composed of countless rubber parts that help them function properly and efficiently. Have you ever considered all of the uses for rubber hoses and seals? Without hoses, seals, grommets, O-rings and so many other rubber parts, most everyday items would leak, fall apart or otherwise malfunction.

Since rubber parts play such an integral role in product function and design, manufacturers have to be careful to assemble them properly to avoid problems down the line. While this sounds simple enough in theory, the reality is that assembling rubber parts can be quite difficult.

The slip-resistant nature of rubber makes it difficult to install, cut, remove or manipulate. Improper part alignment or installation can lead to part failure and safety issues. Repair and installation of rubber parts can take considerable physical effort and time.

Temporary assembly lubricants help solve this problem. When applied to rubber parts, temporary assembly lubricants reduce friction during assembly to make installation easier. Once dry the slipping action goes away and parts stay in place.

What is the best way to apply temporary lubricants to rubber parts? Brushing, sponging, spraying, dunking and dipping are all effective manual application methods. Since each assembly process is unique, the best method is often based on personal preference.

Watch this short video for International Products Corporation’s (IPC) suggestions for assembling hoses and seals with P-80® temporary assembly lubricants:

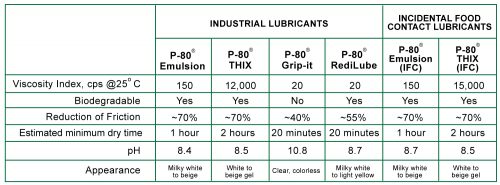

P-80 temporary assembly lubricants are water-based and do not contain alcohol or petroleum distillates, so they will not cause rubber to swell, dry out or harden. And, they do not contain silicon or other persistent ingredients, so once dry the slipping action goes away and parts stay in place. P-80 lubricants are free of hazardous ingredients, making them safe for workers and the environment. Most P-80 products are biodegradable.

Want to learn more about P-80 temporary assembly lubricants?

Contact IPC’s technical team or request a free sample.

Tweet

Print

Print