Are You Using Your Cleaner At The Right Temperature?

Tweet

Print

Print

Establishing a cleaning regimen is no easy feat. So many factors need to be considered: soils, substrates, cleaning method, choice of detergent, length of cleaning cycle, amount of cleaner needed and cleaning temperature. By carefully considering all of these factors, you are on your way to setting up a cleaning protocol that is both effective and economical.

So, you’ve done your homework and you’re almost there. You’ve gathered the materials you need to clean, identified the soils, figured out your cleaning  method and the length of your cleaning cycle, chosen the best specialty cleaner, and even figured out how much cleaner you need to use. But, how do you determine the optimal cleaning temperature?

method and the length of your cleaning cycle, chosen the best specialty cleaner, and even figured out how much cleaner you need to use. But, how do you determine the optimal cleaning temperature?

Generally speaking, higher temperatures mean improved results. But, how do you know when the temperature is too high? Since each cleaning application is unique, careful consideration should be made when determining the optimal operating temperature. Consider these factors:

- What are you cleaning? Different substrates react to heat in different ways. Be aware of the temperature sensitivity of the surfaces you are cleaning. Follow manufacturer’s guidelines if available.

- What are the soils? Isn’t all dirt created equal? Absolutely not! Some soils are far more stubborn than others. Tougher soils often require higher temperatures.

- What is your cleaning method? Different cleaning methods will produce different results. The best operating temperature will vary based upon whether you are using a manual, ultrasonic, immersion, CIP (clean in place), automatic (either mild or high agitation), or pressure washing system.

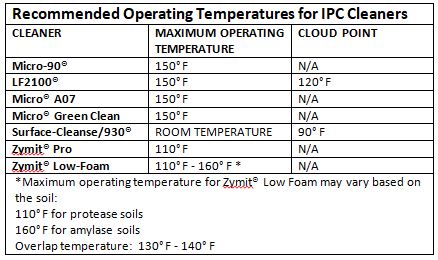

- What cleaner are you using? Each cleaning product operates best at different temperatures. The best way to know the maximum operating temperature of your cleaner is to consult with the manufacturer.

What’s the risk of raising the temperature too much? If increasing the temperature is one of the best ways to speed up or improve the cleaning action, why not just crank up the heat? Using too high a temperature may cause problems:

- Worker Injury: Extreme high temperatures can cause burns. Skin contact with cleaning solutions at temperatures above 150° F becomes much more dangerous than at lower operating temperatures. Higher temperatures require

shorter exposure times to inflict burns.

shorter exposure times to inflict burns. - Damage to Materials: Certain objects can withstand heat better than others. Most glass objects, for example, can bear higher temperatures than some plastics. The objective is to clean the surface…not destroy it.

- Destruction of Enzymes: Protease enzymes are catalysts that break down protein based soils. However, too much heat can destroy the enzymes and the soils will remain.

- Separation of the Cleaning Solution: Depending on their chemical composition, some cleaners can begin to separate – or come out of solution – at higher temperatures. The temperature at which this occurs is referred to as the cloud point, and is evidenced by the composition turning cloudy. If you notice that your cleaning solution begins to look cloudy you’ve reached the cloud point. Raising the temperature beyond the cloud point causes the ingredients to come out of solution, which reduces the detergency.

Learn the optimal operating temperatures for the cleaners you are using. A little bit of knowledge is your best tool. Consult the manufacturer for the suggested operating temperatures for your detergent.

Your best source of technical guidance is the manufacturer of your specialty cleaner. Choose a cleaning product from a company that will continue to work with you long after the sale, offering technical support and guidance. International Products Corporation (IPC) assists their customers with validation methods and product testing. IPC has an on-site lab that works with customers to offer material compatibility testing, process and validation development, and residue analysis. Learn more here.

So, how do you make sure you are setting up a cleaning protocol that is both effective and economical? By carefully considering all of the above variables and relying on the support provided from the manufacturer of your cleaner.

Need help choosing the right specialty cleaner and determining the optimal operating temperature for your cleaning application? Visit IPC’s website or contact one of our technical specialists.

Tweet

Print

Print