What Is The Shelf Life Of My Assembly Lubricant? (And, Why It Matters)

Tweet

Print

Print

Remember that temporary assembly lubricant that’s been in your cabinet for years? How do you know if it’s still effective and safe to use? These things are good forever, right?

Absolutely not! Chemical products do indeed have a shelf life. Paying attention to expiration dates helps ensure you are using products at their peak performance levels for optimal results.

What Is Shelf Life?

The shelf life of a product is defined as the “length of time that a commodity may be stored without becoming unfit for use, consumption, or sale.” (https://en.m.wikipedia.org/wiki/Shelf_life). It’s important to note that manufacturers determine the shelf life of a product based upon expectations of normal use and storage. Failure to follow recommended guidelines can limit the expected shelf life of any product.

How Is Shelf Life Determined?

While each product and each manufacturer is unique, shelf life is generally determined by assessing product stability under normal conditions over an extended period of time. Are the active ingredients still effective or have they deteriorated? Chemical composition and anticipated environmental factors both have a role in determining a product’s shelf life.

Product quality can be assessed by determining the concentration of key ingredients. Once the active ingredients of a product begin to degrade, product strength may be diminished.

Environmental factors include temperature, moisture and exposure to air. External contaminants or stresses can also affect product quality.

What Is The Shelf Life of My Lubricant?

All of IPC’s P-80® Temporary Assembly Lubricants have a two-year shelf life.

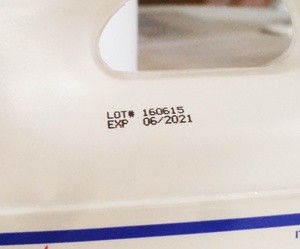

Is This Information On the Product Container?

All of IPC’s products are stamped with a six-digit lot number that signifies the date of manufacture (YY/MM/DD). For example, a lot number of 190301 signifies that the product was manufactured on March 1, 2019. The product expiration date is stamped directly below the lot number.

How Does IPC Calculate Shelf Life?

The shelf life of IPC’s products is determined by observation and testing. Part of the manufacturing process includes retaining a sample of each lot number produced for quality control.

To determine the shelf life of its P-80 Temporary Assembly Lubricants, IPC tests for changes in pH and viscosity. IPC also observes the product for any changes in appearance or separation.

What Other Factors Affect Shelf Life?

The manner in which products are handled by the end user may also influence shelf life. It’s always a good idea to follow the manufacturer’s recommendations for storage and handling. Follow these steps to maintain product quality and get the most out of your lubricant:

- Store at recommended temperatures

- Properly close containers between use – do not leave bottles uncapped

- Do not mix with other chemicals

- Use clean tools to avoid introducing contaminants

- Do not dilute

- Follow manufacturer’s instructions for use

What Happens If I Use My Temporary Assembly Lubricant After The Expiration Date?

Using products beyond their expected expiration date is not recommended. After the expiration date your lubricant may no longer offer the same amount of lubricity which can have an impact on your entire assembly process. If you have questions about whether or not it’s okay to use your product, contact the manufacturer for assistance.

Have questions about temporary assembly lubricants? Want a free sample for testing? IPC can help!

Tweet

Print

Print