An Easy Guide to Understanding How Surfactants Work

Tweet

Print

Print

What is a Surfactant?

Surfactants are a primary component of cleaning detergents. The word surfactant means surface active agent. As the name implies, surfactants stir up activity on the surface you are cleaning to help trap dirt and remove it from the surface.

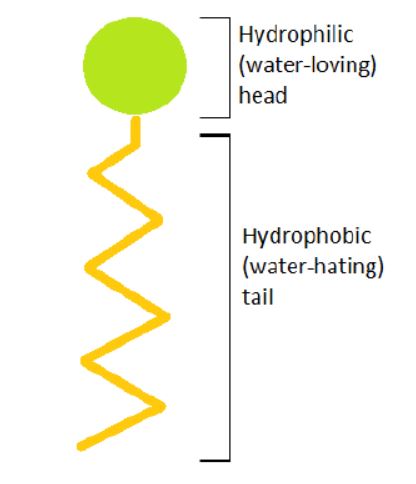

Surfactants have a hydrophobic (water-hating) tail and a hydrophilic (water-loving) head. The hydrophobic tail of each surfactant surrounds soils. The hydrophilic head is surrounded by water.

How do surfactants work?

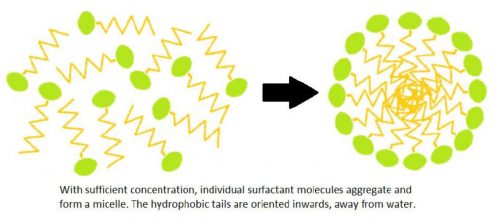

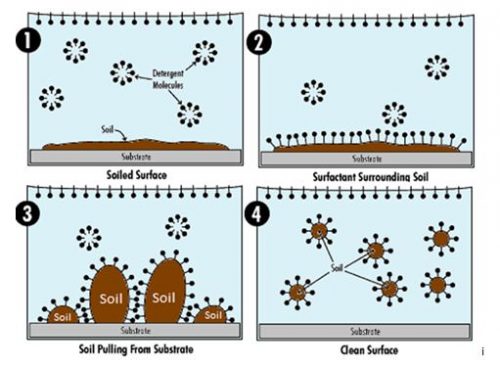

When there are a sufficient amount of surfactant molecules present in a solution they combine together to form structures called micelles. As the micelle forms, the surfactant heads position themselves so they are exposed to water, while the tails are grouped together in the center of the structure protected from water.

The micelles work as a unit to remove soils. The hydrophobic tails are attracted to soils and surround them, while the hydrophilic heads pull the surrounded soils off the surface and into the cleaning solution. Then the micelles reform with the tails suspending the soil in the center of the structure.

Types of Surfactants

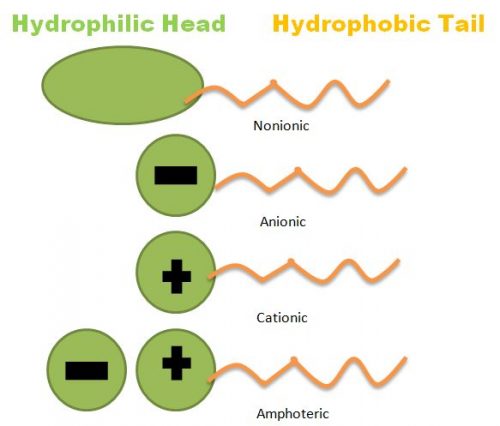

The hydrophilic head of each surfactant is electrically charged. The charge can be negative, positive, or neutral. Depending on the charge of the hydrophilic head, the surfactant is classified as anionic, nonionic, cationic or amphoteric.

Anionic Surfactants

Anionic surfactants have a negative charge on their hydrophilic end. The negative charge helps the surfactant molecules lift and suspend soils in micelles. Because they are able to attack a broad range of soils, anionic surfactants are used frequently in soaps and detergents. Anionic surfactants create a lot of foam when mixed. While anionic surfactants are excellent for lifting and suspending particulate soils, they are not as good at emulsifying oily soils.

Sulfates, sulfonates, and gluconates are examples of anionic surfactants.

Nonionic Surfactants

Nonionic surfactants are neutral, they do not have any charge on their hydrophilic end. Nonionic surfactants are very good at emulsifying oils and are better than anionic surfactants at removing organic soils. The two are frequently used together to create dual-action, multi-purpose cleaners that can not only lift and suspend particulate soils, but also emulsify oily soils.

Certain nonionic surfactants can be non-foaming or low-foaming. This makes them a good choice as an ingredient in low-foaming detergents.

Nonionic surfactants have a unique property called a cloud point. The cloud point is the temperature at which the nonionic surfactant begins to separate from the cleaning solution, called phase separation. When this occurs, the cleaning solution becomes cloudy. This is considered the temperature for optimal detergency. For low foaming cleaners, optimal detergency is at the cloud point; for foaming cleaners optimal detergency is either just below the cloud point or at the start of the cloud point. The agitation of low foaming cleaners is sufficient to prevent phase separation.

The temperature of the cloud point depends upon the ratio of the hydrophobic and hydrophilic portions of the nonionic surfactant. Some cloud points are at room temperature while others are very high. Some nonionic surfactants don’t have a cloud point because they have a very high ratio of hydrophilic to hydrophobic moieties.

Examples of some common nonionic surfactants include cocamide, ethoxylates, and alkoxylates.

Cationic Surfactants

Cationic surfactants have a positive charge on their hydrophilic end. The positive charge makes them useful in anti-static products, like fabric softeners. Cationic surfactants can also serve as antimicrobial agents, so they are often used in disinfectants.

Cationic surfactants cannot be used with anionic surfactants. If positively charged cationic surfactants are mixed with negatively charged anionic surfactants, they will fall out of solution and no longer be effective. Cationic and nonionic surfactants, however, are compatible.

Examples of some common cationic surfactants include alkyl ammonium chlorides.

Amphoteric Surfactants

Amphoteric surfactants have a dual charge on their hydrophilic end, both positive and negative. The dual charges cancel each other out creating a net charge of zero, referred to as zwitterionic. The pH of any given solution will determine how the amphoteric surfactants react. In acidic solutions, the amphoteric surfactants become positively charged and behave similarly to cationic surfactants. In alkaline solutions, they develop a negative charge, similar to anionic surfactants.

Amphoteric surfactants are often used in personal care products such as shampoos and cosmetics. Examples of some frequently used amphoteric surfactants are betaines and amino oxides.

How Surfactants are used in Cleaners

Surfactants are a key ingredient in cleaning products. One thing that differentiates cleaning products is how they are made. Cleaners made from a single chemical, targeting a specific type of soil, are referred to as commodity cleaners. Cleaners that are blends of various chemical ingredients designed to work together to remove various types of soils are referred to as formulated cleaners.

Formulated cleaners usually contain four basic elements: surfactants, hydrotropes, builders and carriers. Hydrotropes are chemicals that keep the otherwise incompatible surfactants and builders stable in a solution. The carrier is either water or a solvent. These elements work together to create mechanical actions to remove soils. The end result is a product that can attack dirt on surfaces with a variety of cleaning mechanisms including emulsifying, lifting, dispersing, sequestering, suspending and decomposing soils of various types. The type of surfactants used in a cleaning product largely determines which soils they will be best at removing.

IPC offers a full line of formulated cleaners that among the safest yet most effective solutions on the market. Request a free sample to test our products for your most challenging cleaning applications.

Tweet

Print

Print